【Revolutionizing Laminated Cores】 Ultra-Thin Silicon Steel with Self-bonding Layer Technology news

Self-Bonding ES Core & In-Die Gluing ES Core

Electrical Steel (ES) is widely used in equipment such as motor cores, generators, and transformers, serving as a key material to enhance the performance of these devices. In the lamination process of motor cores, traditional welding or riveting techniques can lead to performance losses, impacting motor efficiency. The glue bonding motor core technology, however, achieves more efficient assembly without the need for welding or riveting, reducing eddy current losses and hysteresis losses. It minimizes the performance loss of the core during production, thereby reducing energy consumption and operational costs. Glue bonding is critical to enhancing motor performance, especially for high-efficiency motors and electric vehicles, as it reduces energy consumption and extends battery life. Additionally, glue bonding technology strengthens the core structure, reducing vibration and noise during motor operation, particularly improving the bonding strength of the teeth, which helps enhance winding and assembly processes. With the growing demand for thinner materials, high-strength, high-speed, low-vibration, low-noise, and high-efficiency motors, glue bonding technology is set to become a key technology in the future core manufacturing industry.

Self-Bonding Iron Core

As a leader in Taiwan's motor core industry, I-HSIN is committed to enhancing product performance. In collaboration with China Steel Corporation, I-HSIN leads the industry in adopting the latest thin silicon steel combined with self-bonding layer technology. This promotes the application of self-bonding silicon steel across various industries, providing customers with more efficient and high-quality solutions. In recent years, I-HSIN has worked with renowned domestic and international customers, applying self-bonding ES core in a variety of advanced products such as electric vehicles, electric motorcycles, drones, compressors, servo motors, and DD motors, driving technological upgrades and market expansion in related industries.

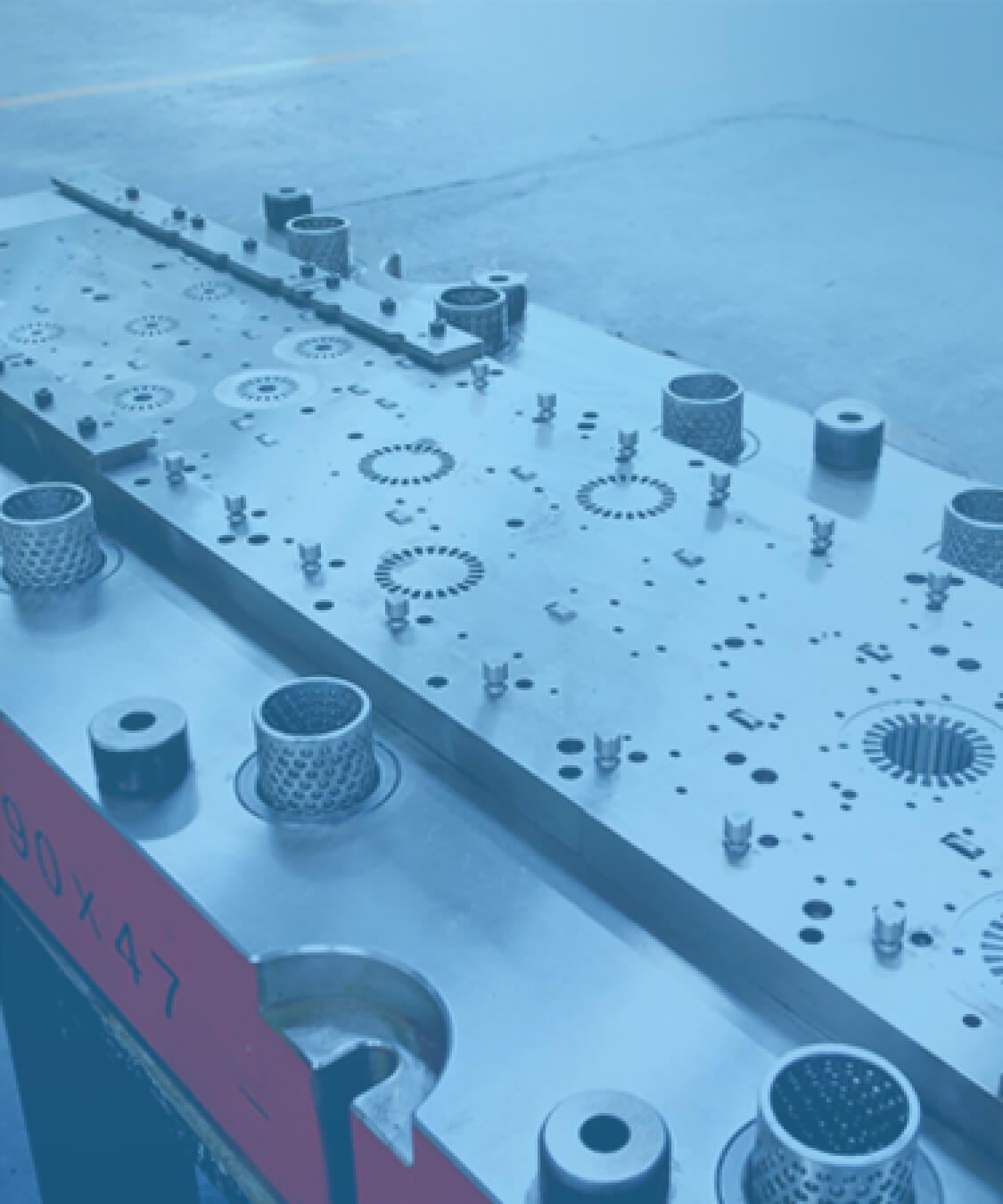

In-Die Gluing

In-die gluing is an advanced process technology that uses specialized gluing machines and die to precisely apply adhesive to designated areas of silicon steel during high-speed stamping, ensuring a stable connection between laminations. In 2020, I-HSIN and Nanjing KYOSEI, obtained Japanese patent authorization for the in-die gluing technology. Nanjing KYOSEI patented gluing technology meets the demands for high-precision control to prevent glue overflow, teeth point gluing, and dual gluing of teeth point, improving teeth bonding strength. In-die gluing enhances production efficiency, shortens processing time, and reduces labor costs. It also improves product consistency and stability while reducing defects. This technology can handle cores of various shapes and sizes, offering high flexibility and customization capabilities.

I-HSIN has already invested in implemented baking furnaces and automated induction heating lines to ensure mass production and stable quality of glue bonding motor core. Moving forward, I-HSIN looks forward to collaborating with more companies to develop ultra-thin, low iron loss, high magnetic flux, and high-strength motors, driving technological innovation in the motor industry and offering more efficient and high-quality product options for worldwide customers.